Introduction

Hypochlorous acid (HOCl) is a powerful disinfectant and oxidizing agent used in a wide range of industries, including healthcare, water treatment, food safety, and surface disinfection. It is particularly valued for its ability to kill bacteria, viruses, and fungi effectively, making it an essential component in cleaning products and sanitizers. The growing awareness of hygiene and sanitation, particularly in the wake of global health concerns, has significantly increased the demand for hypochlorous acid. Establishing a hypochlorous acid manufacturing plant presents a lucrative business opportunity. This Hypochlorous Acid Manufacturing Plant Project Report outlines the necessary steps, including market analysis, raw materials, production processes, equipment requirements, and regulatory compliance, to set up a hypochlorous acid manufacturing facility.

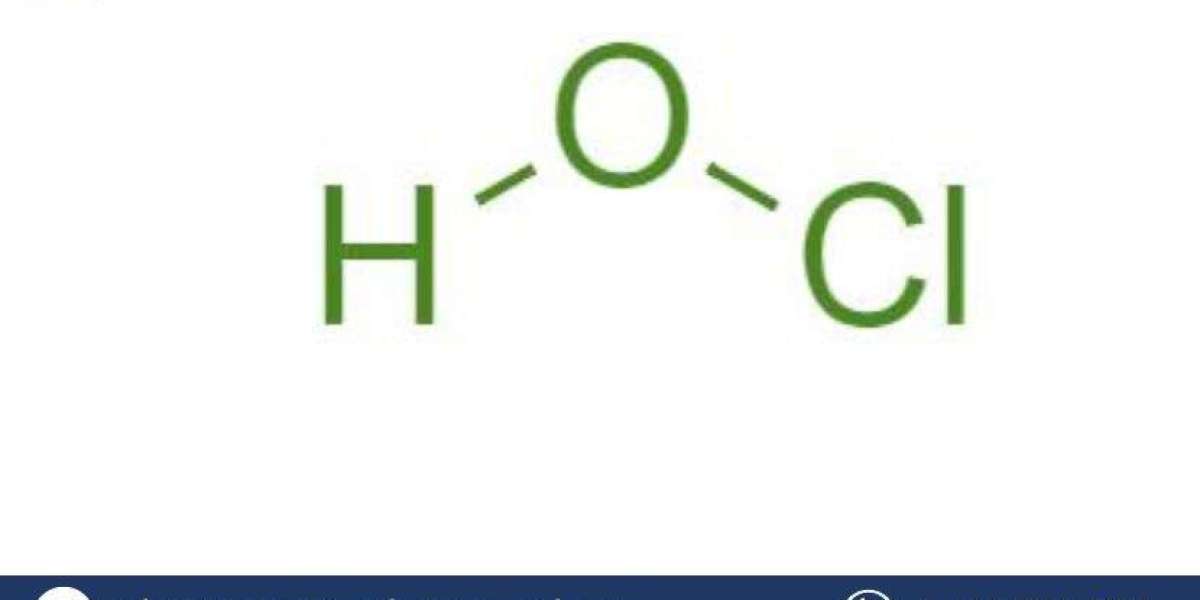

Overview of Hypochlorous Acid

Hypochlorous acid is a weak acid that forms when chlorine dissolves in water. It is a highly effective disinfectant, commonly used in sanitation, water treatment, food processing, and even wound care. Due to its powerful antimicrobial properties, HOCl is preferred in various applications as it is safer to use than other harsher chemicals, making it ideal for consumer goods like disinfecting wipes, sprays, and hand sanitizers. It is also environmentally friendly, breaking down into non-toxic byproducts.

Market Demand and Applications

The demand for hypochlorous acid has surged across multiple industries, driven by:

- Healthcare: As a disinfectant and sterilizer for medical instruments, surfaces, and skin.

- Water Treatment: For purifying drinking water and treating wastewater.

- Food Safety: Used in food processing plants for sanitizing surfaces and washing produce.

- Personal Care: In sanitizing products such as hand sanitizers, wound care solutions, and cosmetic products.

- Industrial Cleaning: Applied in cleaning and sanitizing industrial equipment and surfaces.

With the growing focus on hygiene, especially in hospitals, food facilities, and public spaces, the demand for hypochlorous acid is expected to rise.

Get a Free Sample Report with Table of Contents@

Raw Materials Required

The primary raw materials needed for the production of hypochlorous acid include:

- Chlorine gas (Cl₂): The main component used in the production of HOCl.

- Water (H₂O): The solvent used to dissolve chlorine gas.

- Hydrochloric acid (HCl): Used in certain processes to enhance chlorine dissolution.

These raw materials are relatively inexpensive and readily available, making the cost of production manageable.

Production Process

The manufacturing process of hypochlorous acid involves the following steps:

- Chlorine Gas Generation: Chlorine gas is produced by the electrolysis of sodium chloride (salt) in a brine solution, typically in an electrolytic cell.

- Chlorine Dissolution: Chlorine gas is then dissolved in water to form a mixture of hypochlorous acid (HOCl) and hydrochloric acid (HCl). This process can be done under controlled conditions to ensure the production of a stable HOCl solution.

- Purification and Concentration: The resulting solution is then purified, filtered, and concentrated to the desired strength.

- Quality Control: Rigorous quality control checks are performed to ensure that the hypochlorous acid meets industry standards for strength, purity, and safety.

- Packaging: The final product is packaged in appropriate containers (typically plastic or glass bottles) and labelled for distribution.

Equipment Requirements

To manufacture hypochlorous acid, the following key equipment is required:

- Electrolytic Cells: For chlorine gas generation.

- Reactors and Mixers: To dissolve chlorine gas into water and create a homogeneous mixture.

- Filtration Units: For purifying the solution and removing impurities.

- Concentrators: To adjust the strength of the HOCl solution.

- Quality Control Labs: For testing and ensuring the quality and effectiveness of the product.

- Packaging Machines: For bottling and packaging the final product.

Market and Distribution

The primary markets for hypochlorous acid include:

- Healthcare and Pharmaceuticals: For use in disinfectants, sanitizers, and wound care products.

- Water Treatment: Municipalities and water treatment plants.

- Food Processing and Agriculture: For cleaning food and agricultural products.

- Consumer Goods: In household and industrial cleaning products.

- Personal Care: In skin care and sanitizing products.

Sales can be directed to wholesalers, chemical distributors, hospitals, cleaning companies, food processors, and other industries that require disinfecting solutions.

Regulatory Compliance

The production of hypochlorous acid is subject to various safety and environmental regulations, including:

- Occupational Safety and Health Administration (OSHA): Ensuring the safety of workers involved in the manufacturing process, especially due to the handling of chlorine gas.

- Environmental Protection Agency (EPA): Ensuring that waste disposal and air emissions meet environmental standards.

- FDA Regulations: For products used in food processing or wound care.

- ISO Certification: For quality management systems in the manufacturing process.

It is crucial to ensure compliance with these regulations to maintain product quality, safety, and environmental responsibility.

Challenges

- Safety Concerns: Handling chlorine gas and other chemicals requires stringent safety measures to prevent leaks and accidents.

- Quality Control: Consistent production of high-quality hypochlorous acid is essential for its effectiveness in various applications.

- Regulatory Compliance: The plant must adhere to all local, national, and international regulations regarding chemical manufacturing, storage, and transport.

FAQ

What is hypochlorous acid used for?

Hypochlorous acid is used primarily as a disinfectant and oxidizing agent in healthcare, water treatment, food processing, and industrial cleaning.What are the key raw materials for producing hypochlorous acid?

The main raw materials are chlorine gas, water, and sometimes hydrochloric acid.Is hypochlorous acid safe for use in consumer products?

Yes, hypochlorous acid is generally safe for use in consumer disinfectants and sanitizers, as it is less toxic than other chlorine-based chemicals.What equipment is needed for manufacturing hypochlorous acid?

The key equipment includes electrolytic cells for chlorine generation, reactors for mixing, filtration units, concentrators, and packaging machines.What industries benefit from hypochlorous acid?

Healthcare, food processing, water treatment, agriculture, and consumer goods industries benefit from hypochlorous acid.What are the regulatory requirements for hypochlorous acid production?

The plant must comply with OSHA, EPA, FDA, and ISO standards to ensure safety, quality, and environmental responsibility.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au